Safe Load Weight Lift Indicator & Visual Alarm Systems

|

:: Industry Wide Problem ::

The loads moved by a typical material handling vehicle come in a variety of different shapes, physical sizes and weights. The majority of the forklift operators will experience some difficulty with problems relating to the theoretical forklift lifting capacity as indicated on the manufacturer’s ID plate and the unknown load weights that are moved within the material operating facilities.

|

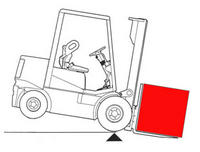

When the weight of the load is not clearly marked and the loads are moved to various lifting heights, there is a danger of the vehicle stability. The travel speed and turning radius that cannot be easily judged will have a substantial effect on the load center of the vehicle. The forklift operator must deal with unknown elements that will have an effect on changes in the vehicle’s center of gravity that has moved outside of the "Stability Triangle" without the operator’s knowledge. It is well know that this can result in the possibility of the vehicle tipping which may cause damage to the goods and the equipment as well as compromising the operator’s safety.

Longitudinal Stability

The axis of rotation when a truck tips forward is the front wheel's points of contact with a pavement. When a powered industrial truck tips forward, the truck will rotate about this line. When a truck is stable, the vehicle moment must exceed the load moment. As long as the vehicle moment is equal to or exceeds the load moment the vehicle will not tip over. On the other hand if the load moment slightly exceeds the vehicle moment, the truck will begin to tip forward, thereby causing the rear to lose contact with the floor or ground and resulting in loss of steering control. If the load moment greatly exceeds the vehicle moment, the truck will tip over.

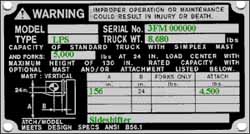

To determine the maximum safe load moment the truck manufacturer normally rates the truck at a maximum load at a given distance from the front face of the forks. The specified distance from the front face of the forks to the line of action of the load is commonly called the load center. To safely operate the vehicle the operator should always check the data plate to determine the maximum allowable weight at the rated load center.

Example: If an operator is operating a 3000 pound lift capacity truck ( with 24" load center), the maximum allowable load moment is 72.000 inch-pounds (3.000 x 24). If a load is 60 inches long ( 30 " load center), then the maximum that this load can weigh is 2.400 pounds (72.000 divided by 30)

Lateral Stability

The vehicle's lateral stability is determined by the line of action's position ( a vertical line that passes through the combined vehicle's and load's center of gravity) relative to the stability triangle. As long as the line of action of the combined vehicle's and load's center of gravity falls within the stability triangle, the truck is stable and will not tip over. Factors that affect the vehicle's lateral stability includes the load's placement on the truck, the height of the load above the surface on which the vehicle is operating and the vehicle's degree of lean.

Dynamic Stability

Up to this point the stability of a powered industrial truck has been discussed without considering the dynamic forces that result when the vehicle and load are put into motion. The weight's transfer and the resultant shift in the center of gravity due to the dynamic forces created when the machine is moving, braking, cornering, lifting, tilting and lowering loads, etc. are important stability consideration.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Definition to understand stability of powered industrial trucks

Center of gravity is the point on an object at which all of the object's weight is concentrated. For symmetrical loads, the center of gravity is at the middle of the load.

Counterweight is the weight that is built into the truck's basic structure and is used to offset load's weight and to maximize the vehicle's resistance to tipping over.

Fulcrum is the truck's axis of rotation when it tips over.

Grade is the slope of a surface, which is usually as a number of feet of rise or fall over a hundred foot horizontal distance ( the slope is expressed as a percent).

Lateral stability is a truck's resistance to overturn sideways.

Line of action is an imaginary vertical line through an object's center of gravity.

Load center is the horizontal distance from the load's edge ( or the fork's or other attachment's vertical face) to the line of action through the load's center of gravity.

Longitudinal stability is the truck's resistance to overturning forward or rearward.

Moment is the product of the object's weight times the distance from fixed point ( usually the fulcrum). In the case of a powered industrial truck, the distance is measured from the point at which the truck will tip over to the object's line of action. The distance is always measured perpendicular to the line of action.

Track is the distance between the wheels on the same axle of the truck.

Wheelbase is a

distance between the centerline of the vehicle's front and rear wheels.

|

The ED2-SLL Series SkidWeigh is an electronic device that can be installed on any forklift truck in order to convert it into a mobile check weighing scale. Every time a skid is picked up, the hydraulic pressure on the forklift is automatically activated and converted to a weight measurement readout in % of vehicle lifting capacity and presented to the operator visually via a large digital six digits LED indicator. |

Installation

:

The ED2-SLL Series SkidWeigh can be installed and calibrated

by a local forklift dealer technician or end user forklift mechanic.

Technical

Data :

Electrical

Voltage 12 V to 55 V DC

Current: Operating 20 mA

Environmental :

Operating temperature -25 ºC to + 70 ºC

Water and dust resistant

Triple shock mounting bracket included

Physical :

120 mm x 80 mm x 55mm

Technology :

Micro Controller

Pressure Transducer :

Standard pressure port connection: 1/4"-18 NPT male thread standard

Optional pressure port : M 12x 1,5

Accuracy: +/- 0.3% of full scale

Repeatability: +/- 0.05% of full scale

Hysteresis: +/- 0.1% of full scale

Stability: +/- 0.2% full scale/yr

Temperature Information :

Compensation: 32° F to 175° F

Drift: +/- 0.03% /50 ° F

Medium: -22° F to 212° F

Ambient: 14° F to 175° F

Storage: -40° F to 212° F

Materials of Construction :

Casing: Stainless steel 1.4305 (AISI 303)

Weight :

95 grams

Shock Sensitivity :

<+/- 0.05% full scale @ 100g for 20 ms

Vibration Sensitivity :

<+/- 0.05% full scale @ 35g & 5-2000Hz

Response Time : < 0.1 ms, 10-90% FS

Frequency Limit : 150 Hz

Proof Pressure, 2,5 x range

Burst Pressure, 2,5 x range

Output, 3 wires 0 - 2,5 V DC

Protection :

Environmental: IP67

Fault :

Reverse polarity

Over voltage

Short circuit

![]() Swiss Made Pressure Sensors

Swiss Made Pressure Sensors

Standard outside thread 1/4"-18 NPT male thread with pressure tip orifice

| Interference Stability | Test Standard | Effects |

| Electrostatic discharge (ESD) | EN 61000-4-2 15 kV air discharge, 6kV contact discharge | No effect |

| High- frequency electromagnetic radiation (HF) | EN 61000-4-6 200mV, 80....1000Mz | No effect |

| Conducted HF interferences | EN 61000-4-6 30V. 0,15...80 Mhz | No effect |

| Fast transients (burst) | EN 61000-4-4 4kV | No effect |

| Surge | EN-6100-4-5 Line-Line, Line-Case 500V, 12Ohm, 9µF | No failure |

| Magnetic fields | EN 6100-4-8 30A/m, 50 Hz | No effects |

| Insulation voltage | 500 VDC ( optional 1000 VDC ) | No effect |

| Interference emit | Test standard | Effects |

| Conducted interference Radiation from housing | EN 55022 0,15... 30Mhz 30... 1000Mhz, 10 meters | No emission |

System Check Weighing Accuracy

:

+/- 0.5% to 1% of forklift lifting capacity

ED2-SLL

Series |

Compact size, Length 120 mm x Height 80 mm x Depth 55 mm

| Patented Technology USA 4,757,712; 4,949,263 Canada 1302566; 1304479 Australia 598,376;605,647 Germany 38811280.0; 3887754.6 EC 0293697; 0351453 |

Integrated Visual Data Technology Inc. Oakville, Ontario, Canada