Universal Check Weighing System for Material

Handling Vehicles

Universal Check Weighing System for Material

Handling Vehicles |

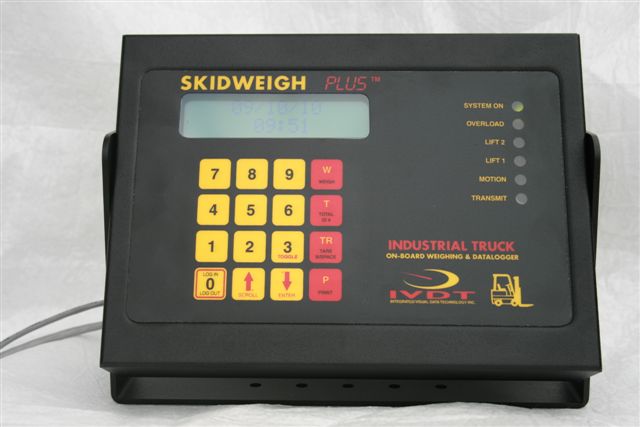

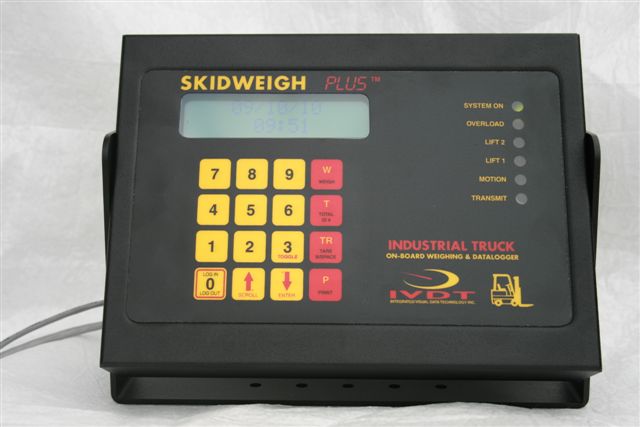

The

SkidWeigh Plus System is a microprocessor based on-board check

weighing system designed to be connected to the electronic pressure

transducer installed in the lift circuit of the material handling

vehicle.

Simple setup and calibration procedures

makes the SkidWeigh Plus the end user's choice for an on-board

check weighing system. All operating and calibration instructions

are in English and are displayed on the LCD display. There are no

codes, complicated keyboard inputs, etc. as found in

other systems.

Sample

of the LCD Messages

System check weighing accuracy is

+/- 0.5 to 1% of the vehicle's lift capacity. |

|

SP1000-Series

-

Saves time consuming trips to

and from fixed scales

-

Saves time through stock inventory

taking by weight

-

Prevents overloading of lift

trucks and racking

-

Check weights of incoming suppliers

and outgoing products

-

Freight weight verification

-

Will not reduce lifting capacity

of the vehicle

-

Helps reduce truck wear and tear

-

Can be installed on any material

handling vehicle

|

click

on image to enlarge

|

click on image to enlarge

|

Load

Weight Printout Ticket

Date: 95/02/24

Time:

11:34

Oper.ID:

12011

Vehicle #:

102

Dept.#:

12

Way #: 17889

# of WRT:

4

Tot. Weight:

1215 lb

Active

Session Stats Printout Ticket

Date:

95/02/24

Time:

11:47

Oper.ID:

12011

Vehicle#:

102

Dept.#:

12

Login:

08/34/57

Session Time: 03:13:23

St Time Unld:

00:37:33

St Time Ldd:

00:53:11

Dr Time Unld:

01:30:16

Dr Time Ldd:

01:31:34

Total Lft Time: 00:08:44

# Low Lifts:

17

# Med Lifts

47

# High Lifts:

4

Wght Lifted:

36240 lb

# W Readings:

34

Event

Count Time

1

0 0:00:00

2

0 0:00:00

3

0 0:00:00

Closed

Session Stats Printout Ticket

Date:

95/02/24

Time:

17:04

Oper.ID:

12011

Vehicle#:

102

Dept.#:

12

Login:

08/34/57

Logout:

17:04

Session Time: 08:29:37

St Time Unld: 01:23:45

St Time Ldd:

01:30:18

Dr Time Unld: 02:12:56

Dr Time Ldd:

02:46:32

Tot Lft Time:

00:36:56

# Low Lifts:

178

# Med Lifts:

104

# High Lifts:

41

Wght Lifted:

72890 lb

# W Readings:

133

Event Count

Time

1

0

2

0

3

0

Waybill

Report

Way #:

5578

# of WRT:

4

Tot. Weight: 12400

Way #:

5579

# of WRT:

2

Tot. Weight:

4360

Way #:

5580

# of WRT: 12

Tot. Weight:

18700

etc.

Technical

Data

Electrical

- Voltage: 12 to 55 V DC

Monitor Display

- 2 lines x 16 characters LCD (super twist )

- LED backlight

- Large character size (4.84 x 8.06 mm)

- Temperature range -100 ºC to 50 ºC

Environmental

Operating temperature

- (-10 ºC to +50 ºC)

- Humidity up to 90%, no condensation

Enclosure

- Water and dust resistant

- Machined aluminum

- Universal mounting bracket

Physical

- Length: 242 mm

- Width: 151 mm

- Depth: 44 mm

- Weight: 1100 g

Alphanumeric Keyboard

- Enlarged 16 key with tactile feedback

- Audible key signal during data entry

- Sealed keyboard, watertight

- Functions overlay

Status Indicators

- System On

- Overload ( Lift 3 )

- Lift 2

- Lift1

- Motion

- Transmitting

Scrolling Features

- Allows overall status and session statistics to be displayed

Automatic Time-Out Function

- Automatic recovery to user mode after 7 seconds if operator

does not complete input instructions

Real Time Clock

- Continuous operation

- Hours / Minutes

- Year / Month / Day

EPROM

- Up to 64 K bytes for application programs

RAM

- Up to 128 K bytes for program and data storage

CPU

- Intel 80C320

Monitor Interface

- Serial interface for printer

- Serial interface for IR, RF or link to PC

Communication

- Automatic download of finished sessions

- Up to 9600 baud ( asynchronous )

Monitor calibration

- External calibration via keypad with clear LCD instructions

in English ( No codes )

Calibration Security

- Only a secure ID# to initiate the calibration mode

Pressure Transducer

Standard pressure port connection: 1/4"-18 NPT , male thread standard

Optional pressure port : M 12x 1,5

Accuracy: +/- 0.3% of full scale

Repeatability: +/- 0.05% of full scale

Hysteresis: +/- 0.1% of full scale

Stability: +/- 0.2% full scale/yr

Temperature Information

Compensation: 32 F to 175 F

Drift: +/- 0.03% /50 F

Medium: -22 F to 212° F

Ambient: 14 F to 175 F

Storage: -40 F to 212 F

Materials of Construction

Casing: Stainless steel 1.4305 (AISI 303)

Weight

95 grams

Shock Sensitivity:

<+/- 0.05% full scale @ 100g for 20 ms

Vibration Sensitivity:

<+/- 0.05% full scale @ 35g & 5-2000Hz

Response Time: < 0.1 ms, 10-90%

FS

Frequency Limit: 150 Hz

Proof Pressure, 2,5 x range

Burst Pressure, 2,5 x range

Output, 3 wires 0 - 2,5 V DC

Protection: Environmental:

IP67

Fault

Protection:

Reverse polarity

Over voltage

Short circuit

Swiss Made Pressure Sensors

Swiss Made Pressure Sensors

Standard

outside thread 1/4"-18 NPT male thread with pressure

tip orifice

| Interference

Stability |

Test

Standard |

Effects |

| Electrostatic discharge (ESD) |

EN 61000-4-2

15 kV air discharge, 6kV contact discharge |

No effect |

| High- frequency electromagnetic radiation (HF) |

EN 61000-4-6

200mV, 80....1000Mz |

No effect |

| Conducted HF interferences |

EN 61000-4-6

30V. 0,15...80 Mhz |

No effect |

| Fast transients (burst) |

EN 61000-4-4

4kV |

No effect |

| Surge |

EN-6100-4-5

Line-Line, Line-Case 500V, 12Ohm, 9µF |

No failure |

| Magnetic fields |

EN 6100-4-8

30A/m, 50 Hz |

No effects |

| Insulation voltage |

500 VDC ( optional 1000 VDC ) |

No effect |

| Interference emit |

Test standard |

Effects |

| Conducted interference Radiation from housing |

EN 55022

0,15... 30Mhz

30... 1000Mhz, 10 meters |

No emission |

Patented Technology USA 4,757,712; 4,949,263 Canada

1302566; 1304479 Australia 598,376;605,647 Germany 38811280.0; 3887754.6

EC 0293697; 0351453

Integrated Visual Data Technology Inc.

Oakville, Ontario, Canada |